The March 28th Quarterly Networking Event at Blum was well received and attended by over 40 participants. The day started with participants enjoying an opportunity to network, followed by a WMCO FedDev... read more →

On Feb 22, 2024, WMCO hosted a tour for members at the Toyota Cambridge Plant. Our tour began at the Experience Center, where our visitors were able to interact with the interactive displays in the showroom. Members were “primed” on what to... read more →

Hello everyone, As you will have seen announced back on October 4, 2023, WMCO has been successful in securing funding for WMCO to help wood manufacturing members in Ontario make digital integration investments. The available funding is the result... read more →

ONBord hosted an engaging and well-received plant tour on January 31, 2024. The event brought together wood manufacturers and suppliers across Ontario to share ideas and learn from one another. ONbord,... read more →

On behalf of the WMCO staff and its Board of Directors, we wish you and your families all the best for the holidays and 2024! 2023 has been a year filled with many... read more →

Unlocking the Future: Highlights from the December 6th Quarterly Networking Event – AI Integration, Digital Adoption, and Economic Forecasting in Focus! The December 6th Quarterly Networking Event was well received... read more →

3 For 1 Plant Tour Success! The event brought together wood manufacturers and suppliers from across Ontario to share ideas, learn from one another, collectively focus their attention, and... read more →

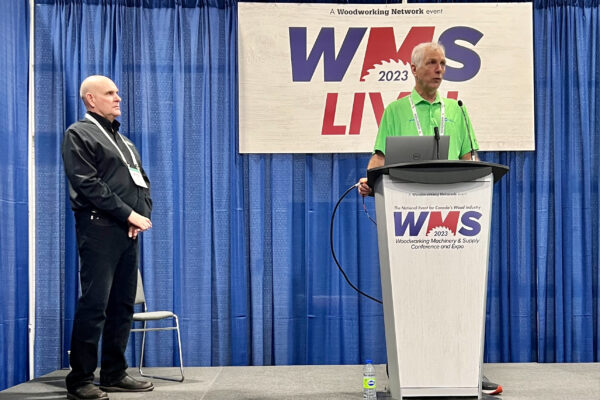

WMCO spent last week busy preparing for and exhibiting at the Woodworking Machinery & Supply Conference and Expo (WMS) – The National Event for Canada's Wood Industry in the... read more →

Government of Canada supports wood manufacturers in southern Ontario - Click here for news releaseFor event materials and to view the slides, click here. Not a member? It’s easy to join! Join Now – Wood Manufacturing Cluster... read more →

WMCO's Spray Finishing Training at Conestoga College had a fantastic turnout! The CEO of WMCO, Mike Baker, stopped by to give a brief introduction and an update on our... read more →