Ending off the summer season, the WMCO placed the spotlight on Woodland Horizon for a plant tour focus group. The event brought together wood manufacturers and suppliers from across Ontario to... read more →

Earlier this year, the WMCO featured a virtual plant tour of Diamond CNC’s previous location, Brantford ON. There, the company showcased their product flow and how the business has... read more →

After years of continued company growth, Diamond CNC, in 2021 decided they had outgrown their current facility. Situated at 116 Copernicus Boulevard, Brantford, it was their second shop they... read more →

The WMCO, in partnership with Archmill House, brought forward a first ever Hybrid – Plant Tour Focus Group event recently this past December. The event successfully bridged the challenge... read more →

On October 28th, WMCO manufacturing member Best Damn Doors opened theirs to a Live Stream Plant Tour Focus Group. WMCO’s Ryan Tabone was on hand to film the event... read more →

Recently the WMCO featured our first Plant Tour Focus Group event as a Live Streamed event. The tour was situated in St. Catharines by a newer manufacturing member to the... read more →

Recently on July 7th, the WMCO hosted a Virtual Case Study/Plant Focus Tour of Tri-Coat Wood Finishing. The event featured a look into how owner Andrew Bauman successfully implemented a... read more →

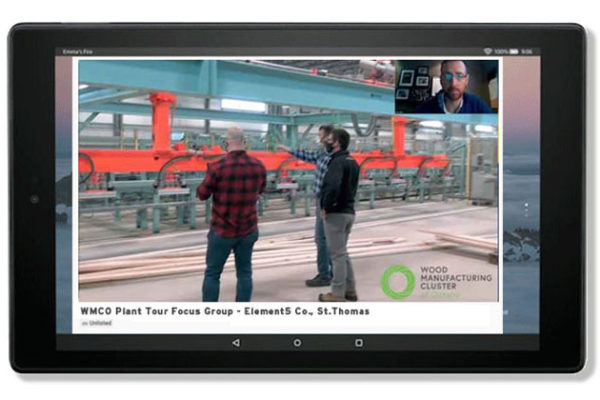

On March 25th, 2021, we hosted our first plant tour focus group under our new name, Wood Manufacturing Cluster of Ontario. Founder of Element5 Patrick Chouinard was on hand... read more →

How do you provide an immersive experience for plant tours when Ontario & Canada grapples with a pandemic and its constraints? Ask the BWA. We are focused on providing you... read more →

On November 21st, members of the Bluewater Wood Alliance attended the Plant Tour Focus Group at Windmill Cabinets located in Chatham, Ontario. The 40,000 sq. ft. facility opened its doors to the... read more →